Identify Problem Shipments Faster with the Wonderment Dashboard

One of the ongoing challenges of shipping right now is being able to understand which packages might just be running a little late, versus being totally lost or waylaid and should be reshipped or refunded. The Wonderment Dashboard is a great resource in this process. Here’s three popular views that help you understand exactly what’s going on:

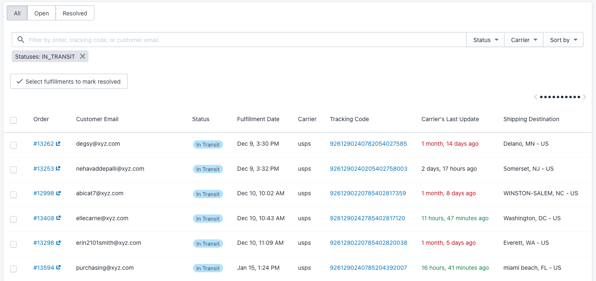

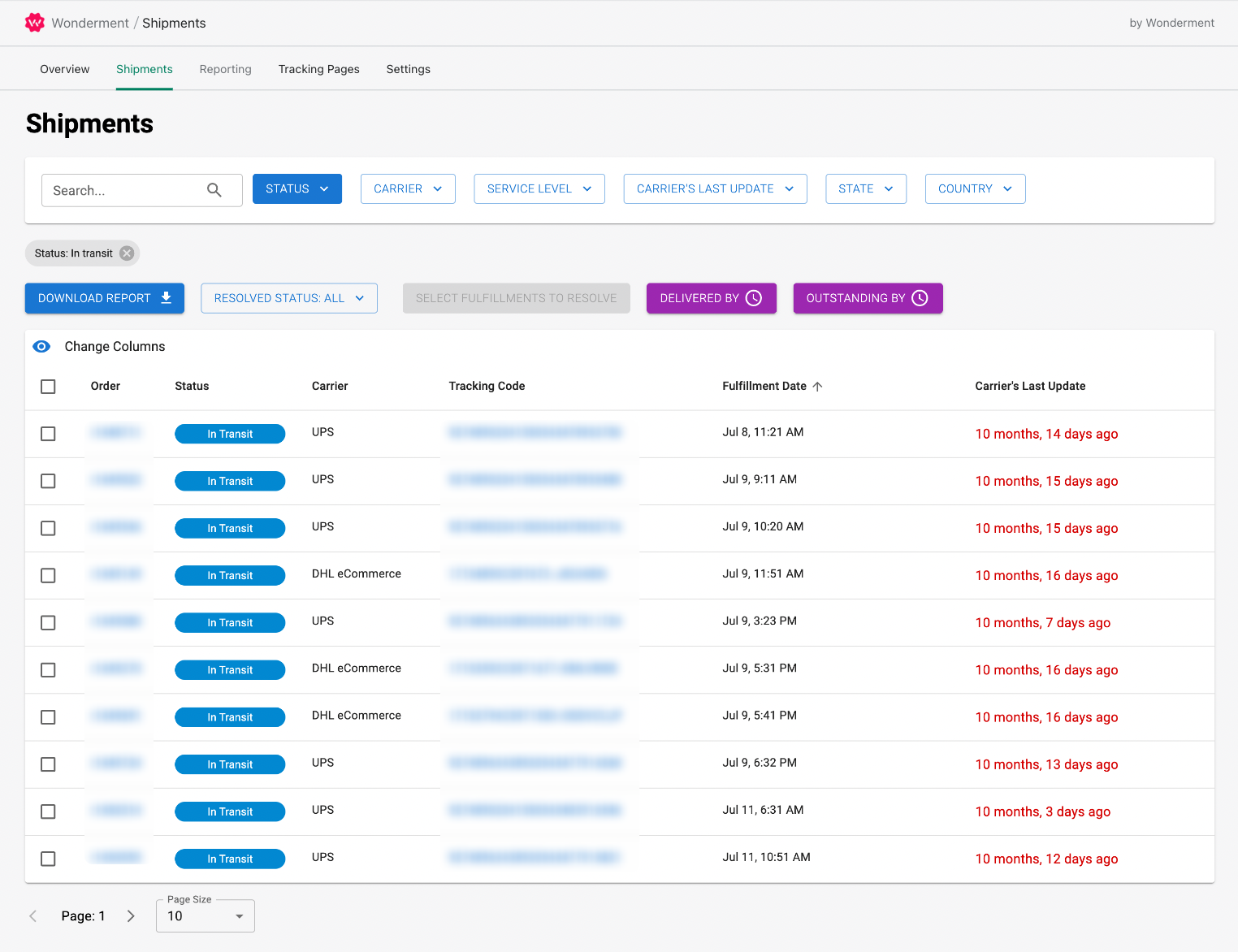

1. Stalled In-Transit Orders, Sorted by Oldest Fulfillment Date

This report reveals if there are orders that are deeply late, and may not have received a tracking update in some time. You can be confident in how widespread a delay is at any given time.

These orders in red haven’t had a tracking update in a month. They’re most likely lost, and should be reshipped, refunded, or otherwise resolved for the customer. Your customers will deeply appreciate proactive outreach, if you show them how you’re going to solve a bad situation. The other orders, while still very late, are at least moving and you probably shouldn’t reship them yet - or find out what the customer needs. Brands that prioritize customer experience have the best results, happiest customers, and healthiest growth.

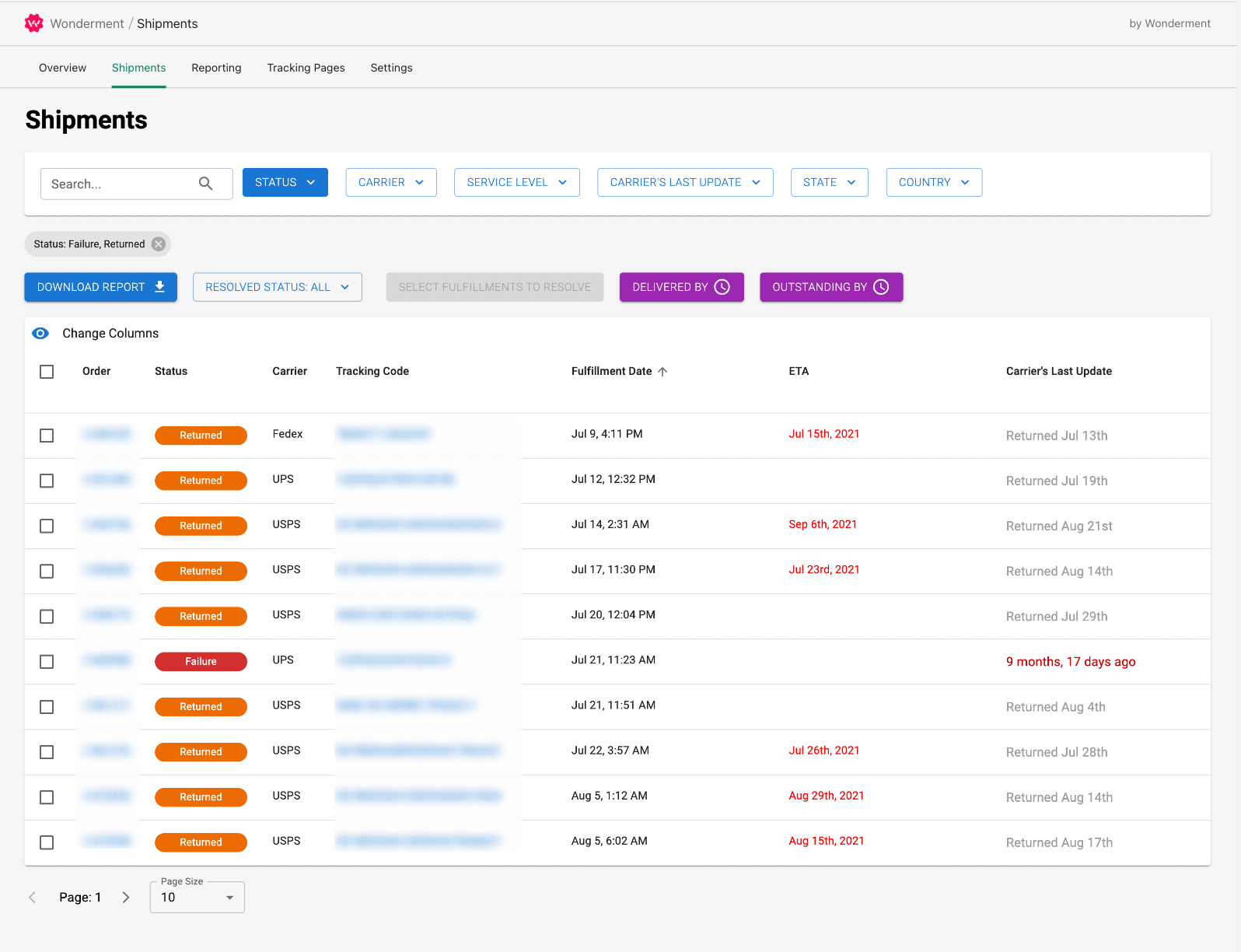

2. Failed and Returned Packages

Developing a system for catching delivery failures and packages returned to sender can help you understand the cracks in your sales and logistics.

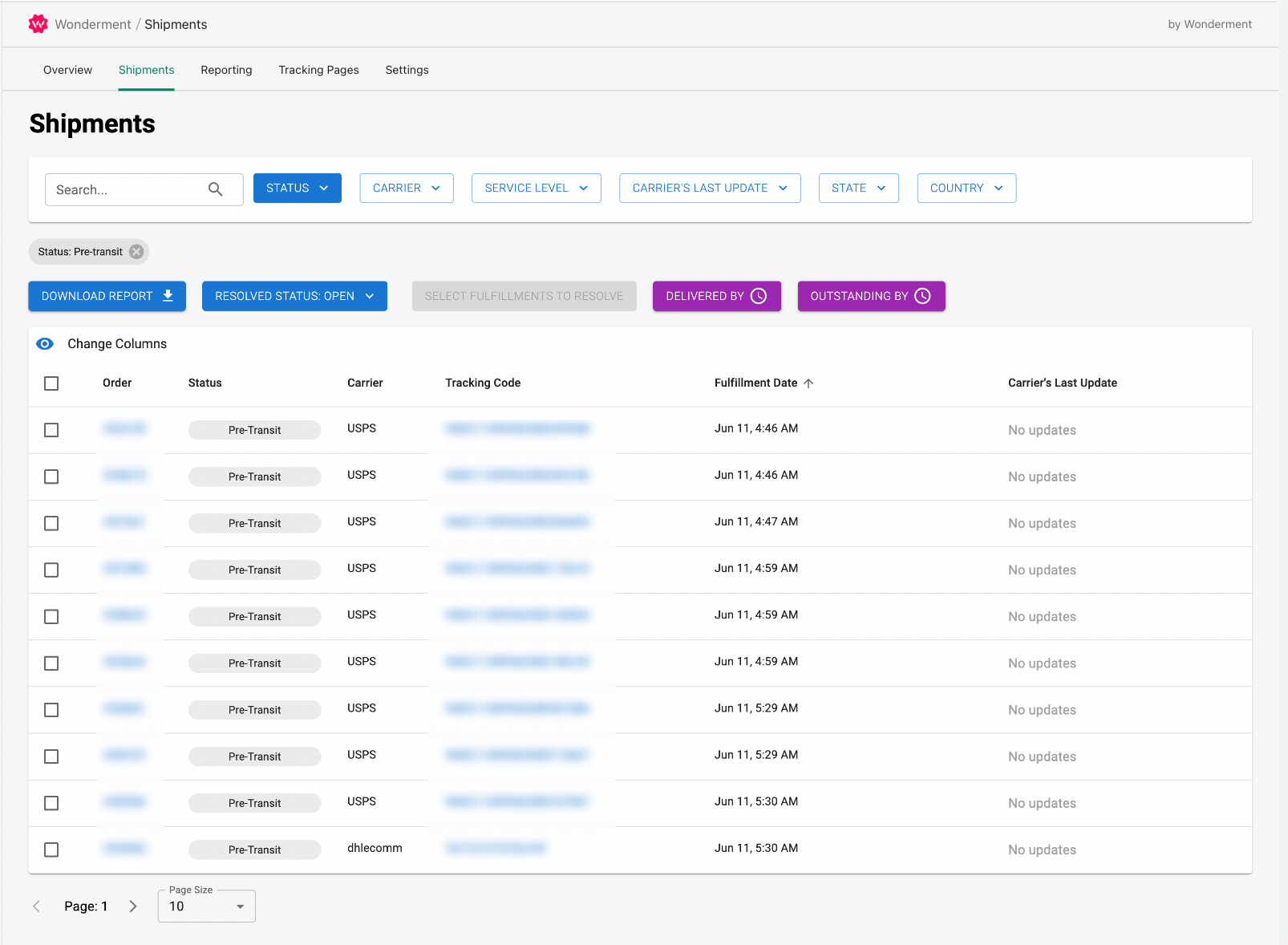

3. Old Orders That Weren’t Picked Up / Stuck in Pre-shipment

The first orders to get a customer complaint will be packages that look like they don’t leave your warehouse for an unacceptably long time. While a carrier might take the blame for slow or poor routing in transit, you (and your logistics partners) will take the blame for a pre-transit shipment that doesn’t make progress shortly after the order was placed. By sorting to Pre-Transit Packages and sorting by the last carrier update time, you can identify orders that haven’t left your warehouse and make sure you don’t have unacceptably old orders waiting to move.

There are so many reasons why this can happen - Sometimes the box or envelope needed ran out, and it sat in the picker’s tray as a result. Sometimes they were dropped off at the carrier, but didn’t get scanned in because of a mistake or were left in the wrong area. Whatever the reason, it’s critical to keep down the number of orders that don’t make progress. If you have week-old orders that haven’t started their journey yet, customers will be frustrated and less likely to return - or justify ordering from more reliable, but higher cost marketplaces like Amazon FBA.